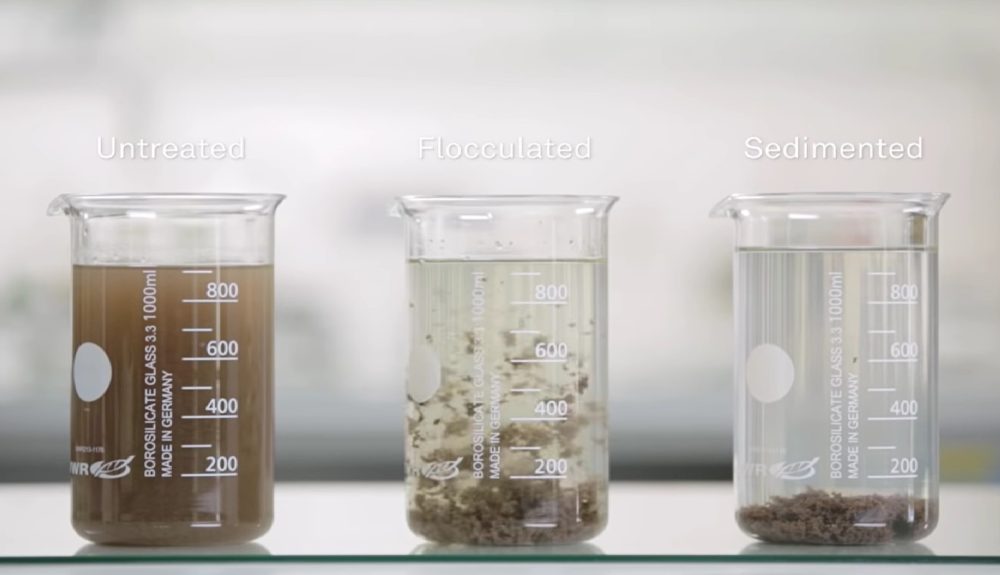

Pretreatment Plant

Enhance the efficiency of your water treatment process by addressing impurities and contaminants at the initial stages. Our pretreatment solutions are tailored to optimize the performance of downstream treatment processes, ensuring the longevity of your water treatment infrastructure.

Deionizers

Precision meets purity in our deionization systems. Eliminate ions and impurities from your water supply, ensuring the highest quality water for your processes. Our deionizers are designed for efficiency, reliability, and long-term cost savings.

Ultrafiltration Machine

Redefine water treatment efficiency with our cutting-edge ultrafiltration machines. From pre-treatment to final filtration, these machines remove even the smallest contaminants, ensuring consistent, high-quality water for various applications.

Reverse Osmosis Plants

Engineered for efficiency and reliability, our RO solutions guarantee the removal of impurities, contaminants, and unwanted particles, delivering water of unparalleled quality for industrial and municipal applications.

Water Waste Management Plant

Effectively manage and treat water waste, ensuring environmentally responsible and sustainable practices. Our solutions are designed to minimize the environmental impact of wastewater discharge and contribute to the circular economy.

Biogas Plant

Embrace sustainability with our biogas-recovery plants. Capture and utilize biogas generated during wastewater treatment, contributing to energy efficiency and reducing your environmental footprint.

Caustic and textile dye recovery plants

Efficiently recovers and reuses caustic solutions and textile dyes, minimizing waste and contributing to sustainable manufacturing practices. Our solutions are tailored to the unique needs of textile industries, ensuring both environmental responsibility and cost-effectiveness.

ETP chemicals

We provide chemicals for Effluent Treatment Plants:

- Urea and DAP

- PAC

- Anionic and cationic polymer

- Water decoloring agent

- Antifoam

- Aluminum sulphate

- Ferric chloride

RO Chemicals

We provide chemicals for Reverse Osmosis Plants:

- Antiscalant

- Sodium metabisulfite (SMBS)

- Biocide

- Cartridge filters and housing

- Membrane acidic cleaner

- Membrane alkaline cleaners

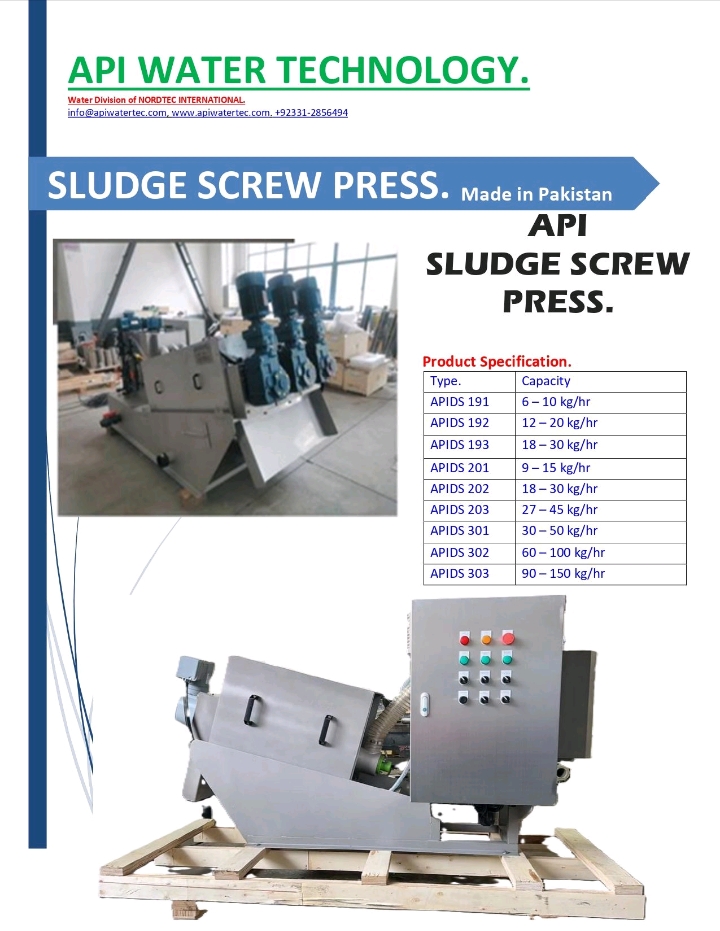

Sludge Screw Press

A sludge screw press is a vital component in an effluent treatment plant, playing a crucial role in the dewatering process of sludge generated during wastewater treatment.

At the heart of the sludge screw press is a robust screw mechanism that applies pressure to the sludge as it moves through a cylindrical screen or filter. The rotating screw auger compresses the sludge against the screen, forcing the water to pass through while retaining the solid particles. This mechanical dewatering process results in a significant reduction in sludge volume, making it easier and more economical to handle and dispose of the remaining solids.

One of the key advantages of a sludge screw press is its ability to achieve high levels of dryness in the dewatered sludge cake. By efficiently removing water from the sludge, the screw press produces a solid cake with a low moisture content, which reduces the overall weight and volume of the sludge for disposal. This not only minimizes transportation and disposal costs but also reduces the environmental impact associated with sludge management.

This innovative technology offers an efficient and cost-effective solution for reducing the volume of sludge by separating the solid and liquid phases.

Tube Diffuser

Tube diffusers play a crucial role in the aeration process of Effluent Treatment Plants (ETP). In an ETP, wastewater undergoes various treatment stages, and aeration is often a primary method used in biological treatment processes like activated sludge treatment.

Tube diffusers are typically submerged in the aeration tanks or basins of ETPs. They release air into the wastewater in the form of fine bubbles, facilitating the transfer of oxygen to microorganisms responsible for breaking down organic pollutants. This aeration promotes microbial growth and activity, which aids in the decomposition of organic matter and other contaminants present in the wastewater.

The design of tube diffusers is optimized to maximize the surface area of contact between air bubbles and the wastewater, ensuring efficient oxygen transfer. They come in various materials like EPDM, silicone, or polyurethane, chosen based on factors such as durability, resistance to chemicals, and oxygen transfer efficiency.

Proper selection, installation, and maintenance of tube diffusers are essential for the effective operation of ETPs, as they directly impact the treatment efficiency and overall performance of the plant.

WASTE WATER TREATMENT PLANT

Consultancy, Designing, Execution & Commissioning,

Waste water recycling, Services.

RO PLANT

Design, Engineering, Installation, Commissioning, Services.

Reverse Osmosis is capable of removing up to 99%+ of the dissolved salts (ions), particles, colloids, organics, bacteria and pyrogens from the feed water (although an RO system should not be relied upon to remove 100% of bacteria and viruses). An RO membrane rejects contaminants based on their size and charge.

ULTRA FILTRATION System

Design, Engineering, Installation, Commissioning, Services.

Hollow fiber membranes.

0.02 micron pore size.

Range of modules from 15 to 114 m² area.

High resistance to chemicals.

Double skinned, preventing bio-fouling penetration.

Low installation, maintenance and operation cost.

PRE-FILTRATION System

Design, Engineering, Installation, Commissioning, Services.

Sand Filter,Carbon Filter, Multimedia filter,Softener,De-Ionizer.

EFFLUENT TREATMENT PLANT. BIO GAS PLANT.

Design, Engineering, Fabrication, Installation, Commissioning, Services.

Capacity: 1600m3/day

Influent COD: 110,000ppm

Influent BOD: 35,000ppm

Bio Gas Production: 65,000m3/day.(55% Methane)

CO2 RECOVERY PLANT

Design, Engineering, Fabrication, Installation,

Commissioning, Services.

Omni Group:

Food grade CO2 Plant Capacity: 24Ton/day.

Shakarganj Sugar Mills Jhang:

Food grade CO2 Plant Capacity: 48Ton/day.

Unicol Distillery Mir Pur Khas:

Food grade CO2 Plant Capacity: 48Ton/day

OIL/MOLASSES STORAGE TANKS

Design, Engineering, Civil Construction, Mechanical Fabrication, Installation, Commissioning, Services

OIL/MOLASSES STORAGE TANKS

Design, Engineering, Civil Construction, Mechanical Fabrication, Installation, Commissioning, Services